Our Solutions

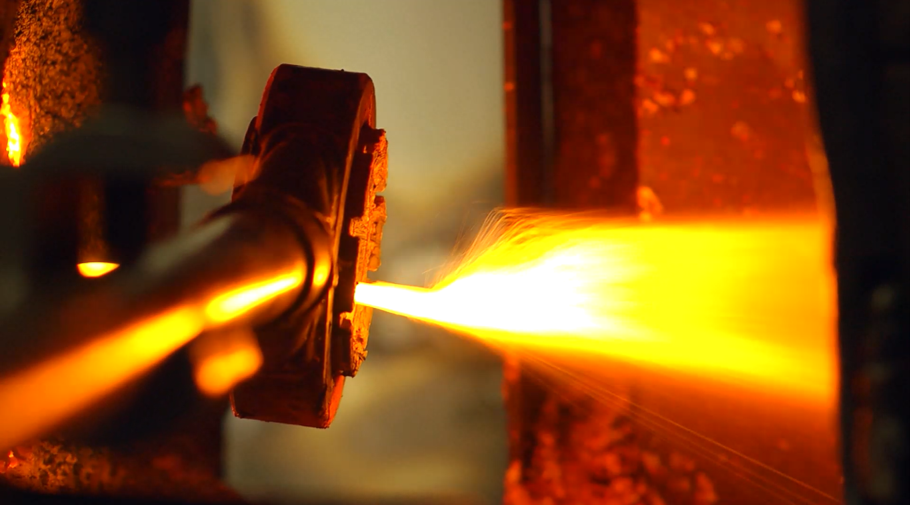

Revolutionizing Industries with Cutting-Edge Technological Solutions – Unleashing the Power of Material Innovation

Creating innovation and value in each and every particle we produce

Metal Powders & Pastes

Global producer of pure metals and alloys in powder, paste and granule forms

Titanium & Master Alloys

Market leader in rotor quality master alloys (including aluminum, vanadium, molybdenum and niobium) used in triple-melted titanium alloys

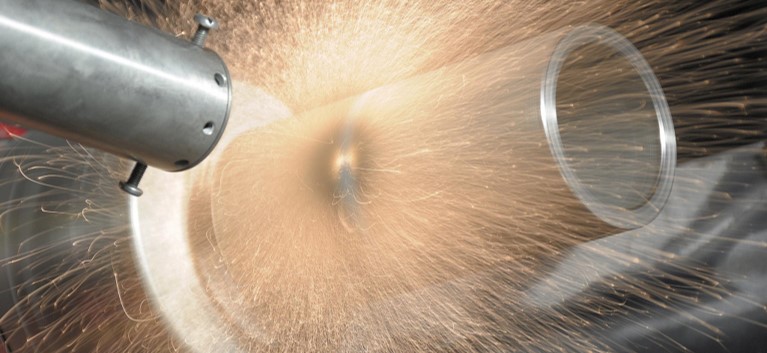

Surface

Technologies

Broad range of specialty coating materials with innovative surface technology solutions and optimized application methods

Integrated Metal Processing

Supporting wide-spread sustainability initiatives and specialty applications through the refinement of feedstocks and value-add technical alloys

Additive

Manufacturing

Primary powder production for custom development to large scale applications, with in-house binder jetting capabilities

Featured News & Innovation

Community, Leadership, and Product News from Kymera

Stay Informed

Explore the latest company news, industry trends and insights from our experts

Kymera's CEO, Barton White, Highlights ESG Commitment and Social Responsibility at MIM2024

Learn MoreAbout Kymera

Pioneers

in materials science™

For over 100 years, we have continually worked to improve operations and exceed customer expectations.

We prioritize research and development to customize the solutions our clients need for their businesses to succeed.

We are committed to being responsible corporate citizens, and we set measurable goals to help achieve long-term objectives.

Our Brand

Kymera

(pronounced kī-ˈmer-ə)

is an adaptation of Chimera, which according to Greek mythology was a massive fire-breathing being, created from the parts of more than one animal. For our company, it symbolizes AmeriTi Manufacturing, CASL Surface Technologies, ECKA Granules, Innobraze, KDF Fluid Treatment, Metallisation Ltd., Reading Alloys, SCM Metal Products, Telex Metals and Thermal Spray Solutions coming together to create one resilient entity. Our logo is a symbol of strength, respect and longevity, combining three powerful animals: namely, the lion, the ram, and the serpent.

Ready for a rewarding career in materials science?

Explore Careers

Join a Team Dedicated to Growth & Innovation

Our commitment to a harmonious blend of unique talents and perspectives fuels innovation and drives our success.

Let’s Get Started

Want to learn more about our products and services? Get in touch with us for more information today.

Learn More